Background

The Spitfire Mk.II incorporated all of the improvements introduced on the Mk.I in production and during service. Its introduction was at a time when high volume aircraft manufacturing facilities was being introduced. The first few Mk.II’s were produced at the Castle Bromwich,Birmingham factory. Ten Mk.II’s were produced in June, twenty seven were produced in July, thirty seven in August and production was up to fifty seven in September.

The Spitfire Mk.II was a Mk.I air frame powered by a 100 Octane fuelled Merlin XII, providing increased performance over the Mk.I. A small fairing on the right side of the nose, immediately behind the propeller was the location of the factory fitted cartridge starter. The Merlin XII was equipped with a motor driven hydraulic pump that retracted the landing gear, so all Mk.IIs abandoned the manual system with the associated large lever. Mk.IIs came out of the factory with full armour protection, including the windscreen,and had rear view mirrors. The laminate seat was feature exclusive to the Mk II. Also standard was the hot air heating system for the eight 7.7mm Browning machine guns. The G.42B camera was fitted to record gun kills. The first MK.II’s were fitted with TR.9D shortwave radios, but these were quickly replaced by TR.1133 VKV units. The latter were characterized by the absence of the aerial wire from the mast behind the cockpit. Another standard feature involved the installation of the IFF system, and this included the aerial wires that led from the fuselage side to the leading edges of the horizontal stabilizers. Significant was the installation of the automatic Rotol RX5 propeller in the form of the RX5/1 [metal] or the RX5/3 [wood]. Some Mk.IIs were equipped with a De Havilland 5/39A propeller, and this was true mainly of the cannon armed Mk.IIb. In all 751 Mk.IIa were built.

The Spitfire Mk.IIa remained in RAF service until the end of 1941 when it was replaced by the Spitfire Mk.V. Many Mk.IIs were subsequently converted to Mk.V standard with the installation of the Merlin 45.

The Kit

Eduard’s intent to explore the earlier marks of the Spitfire is well publicised and this is the first time the company has released a quarter scale Spitfire Mk.IIa as a ProfiPACK. If you have Eduard’s Spitfire Mk.I then a lot of the features of this kit will be familiar and the breakdown of the kit parts has a similar path that other manufactures have approached producing the Spitfire. As with all recent Eduard releases the first thing the draws the eye is the wealth of subtle and consistent recessed detail. You can see a subtle difference between the fasteners and the rivets. It features the slightly raised armour plating around the fuel tank and a couple of air scoops just by the windscreen. Another feature is how fine the attachment points of the parts are to the sprues. There is a little flash here and there and a few sink marks in the exhaust stack, but nothing serious.

There are quite a few plastic and PE parts to detail thecockpit. Eduard has decided to create the cockpit as a separate part. Attention to detail is excellent and includes the full-length Sutton seat harness extending back into the fuselage. The seat has a flare rack moulded on although there is a PE flare rack if you want a slightly more detailed item. The control stick is made up of a number of plastic parts including a PE part. Oddly the instructions show the fitting of the gear retraction pump handle fitted to the Spitfire Mk.I, although the Spitfire Mk.II had a hydraulic pump that operated the main gear. So, you might want to omit this part. The instrument panel [IP] can be done using the pre-coloured photo etched parts, plastic or decal. There are three small sets of decals for the IP. There is some intricate work needed to install the PE hinge for the cockpit door, but a worthwhile one if you’re displaying the door open.

There seems to be a wealth of parts on the clear sprue. You can display the canopy open or closed. The open option has two parts and the closed has just the one, the canopy is moulded onto the rearmost clear part. Eduard has thoughtfully included the clear knockout panel on the port side canopy. There is also an internally fitted mirror [PE] to attach to the canopy.

The fuselage halves are split left and right and are pretty much complete. The only things to add is the one-piece rudder, panelling under the nose and the access door for the cockpit. There are locating pins and holes to aid with the alignment of the two fuselage halves. A third of the wing fillet from the leading edge is separate. If you want to cut out the radio access hatch then Eduard has engineered a hatch demarcation line on the inside of the port fuselage. There is some internal detail for the cockpit just below the sill, but bear in mind the majority of the detail is in the separate cockpit assembly. The one-piece exhausts do have sink marks, but they look easily fixable. The detail of the tips of the exhaust looks very good. Two types of propeller are featured: the Rotol RX5 that was either wood or metal and the de Havilland 5/39A constant speed propeller. The latter was generally fitted to the cannon equipped Mk.IIb’s. The propeller blades are one piece and the spinner is made up from two parts. The rudder is separate and one piece. A little care is needed joining the control surfaces on the tail as there seems to be a sequence to follow.

The almost full span lower wing features separate wing tips.The ailerons are separate and the flaps are in the raised position. The box shaped radiator under the starboard wing is made up from seven plastic including two choices of actuator to display the flap open or closed. PE radiator faces are included for both the under wing radiator and oil cooler. The eight machine gun barrels are included if you want to show them, though you may want to punch holes in the decals representing the canvas barrel covers. The gear down indicators on the upper surface are PE parts and couple of holes need drilling to fit them.

The horizontal tail surfaces are each made up from two parts, though the two elevators are one piece. The tail control surfaces don’t look positionable, but I’m pretty sure with you can cagoule them a little. Care is needed joining the control surfaces on the tail as there seems to be a sequence to follow.

The tyres are devoid of any weighting, though the separate hubs are well detailed. The head on view of the ‘Spit’ in the instructions provides guidance on how to set the oleos and wheels. The subtle rivet detail on the walls of the undercarriage bay is worth noting. There’s a choice of a one piece or three-piece tail wheel.

The majority of the pre-coloured photo etched parts detail the cockpit.

There are paint masks for the outside of the windscreen and canopy. Also included are masks for the hubs, although the parts number on the mask instructions is wrong. There are masks for the single ID light under the fuselage and the gun sight.

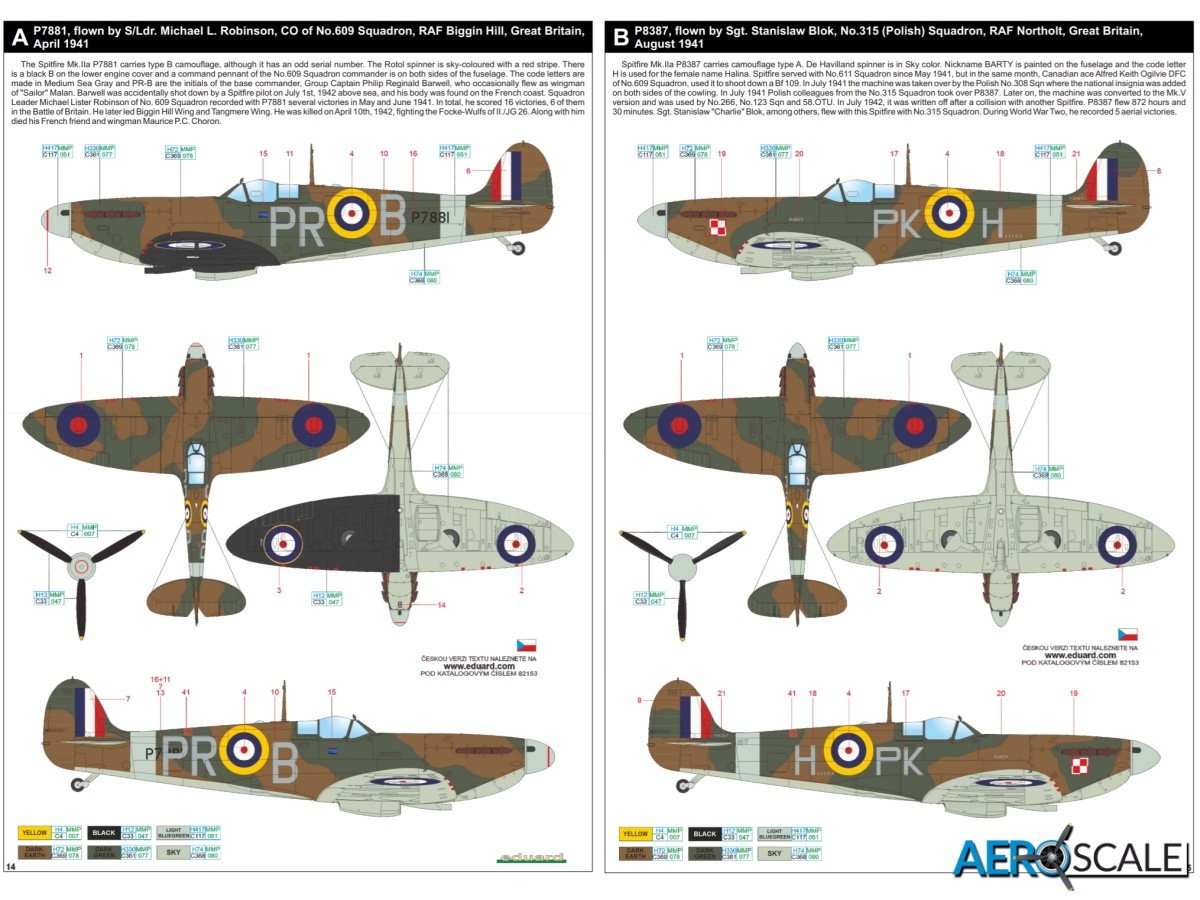

The five marking options include:

Instruction comprises of a twenty-page A4 booklet. The illustrations to aid construction couldn’t be clearer. You will find a full colour painting and marking guide included as well as a page is devoted to applying the stencils.

Conclusion

Its evident from the numerous builds of the Spitfire Mk.I on the internet that very few seem to have a bad word for the kit. The similarities of the Spitfire Mk.II Edition to the Mk.I bodes well for the build of this version

Our thanks to Eduard for the review sample

82153 - Spitfire Mk.II ProfiPACK Edition - 1/48

Please remember, when contacting retailers or manufacturers, to mention that you saw their products highlighted here – on Aeroscale.