Introduction

A new company has come on the scene producing 3D printed tools aimed at the modeller, this new company is called ZEP Systems and is based in Spain. I have a couple of their products to look, one of these are two sizes of sanding tools with a sand area of 65mm X10mm and 100mm X 15mm; the other is three sizes of aircraft model jig that will support a model while you work on it and once it gets to a certain stage the model could be safely kept on the jig. The three offerings are listed as small, medium and large.

Review

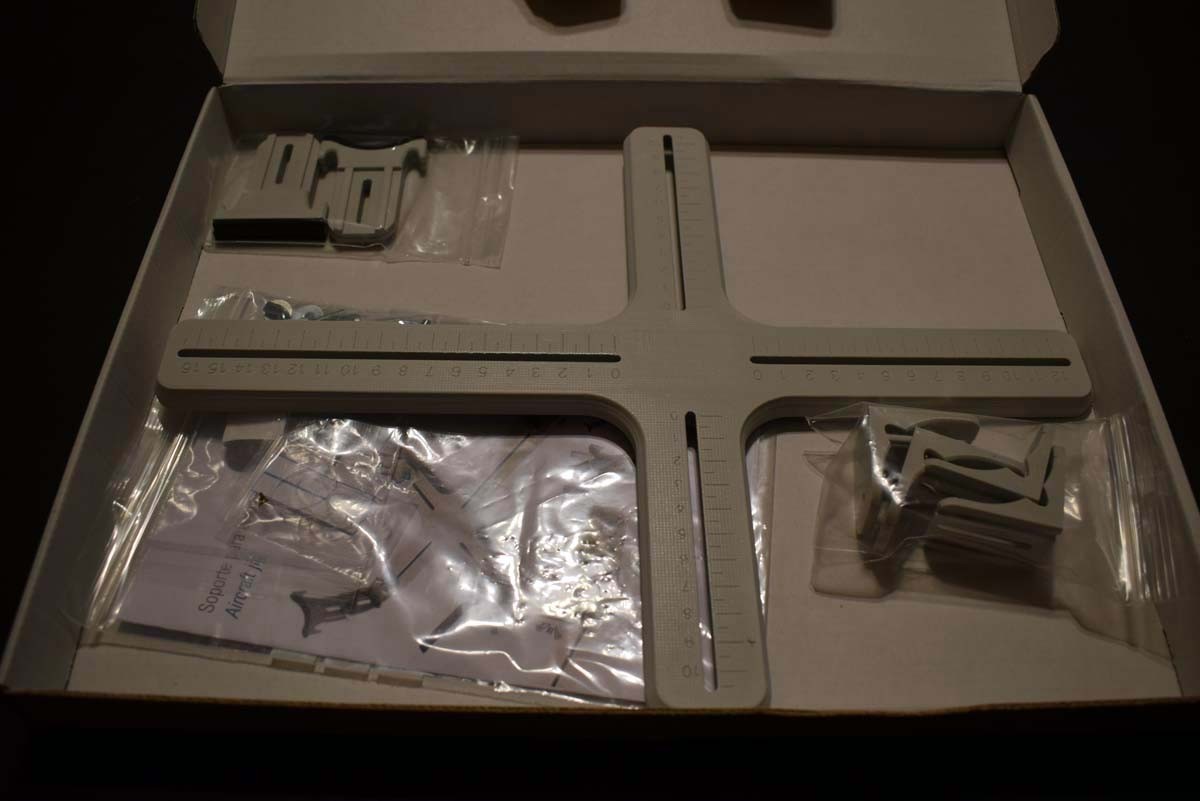

These three offerings all arrive in a flip top box held closed with an information sticker. The sizes available are:

Small 185mm X 255m

Medium 230mm X 310mm

Large 330mm X 410mm

The sizes mentioned are the maximum extension of the support pillars and I have found that by reversing the arms the minimum of all is zero, but with the nuts getting in the way. When you open the box you find the cruciform, 2supports, 2 rounded supports, 4 elbows, 8 butterfly nuts, 8 bolts and 8 washers; there are some bands of an unknown material which can be used to secure a model to the stand. The reason I mention that they are an unknown material is the potential latex allergy issue if that is what they are; If you do not want to take a risk just use cotton or such to secure the model. Depending on the size of jig you purchase there are a number of feet that stick to areas on the underside of the cruciform to prevent movement and scratches to the dinner table.

Assembly

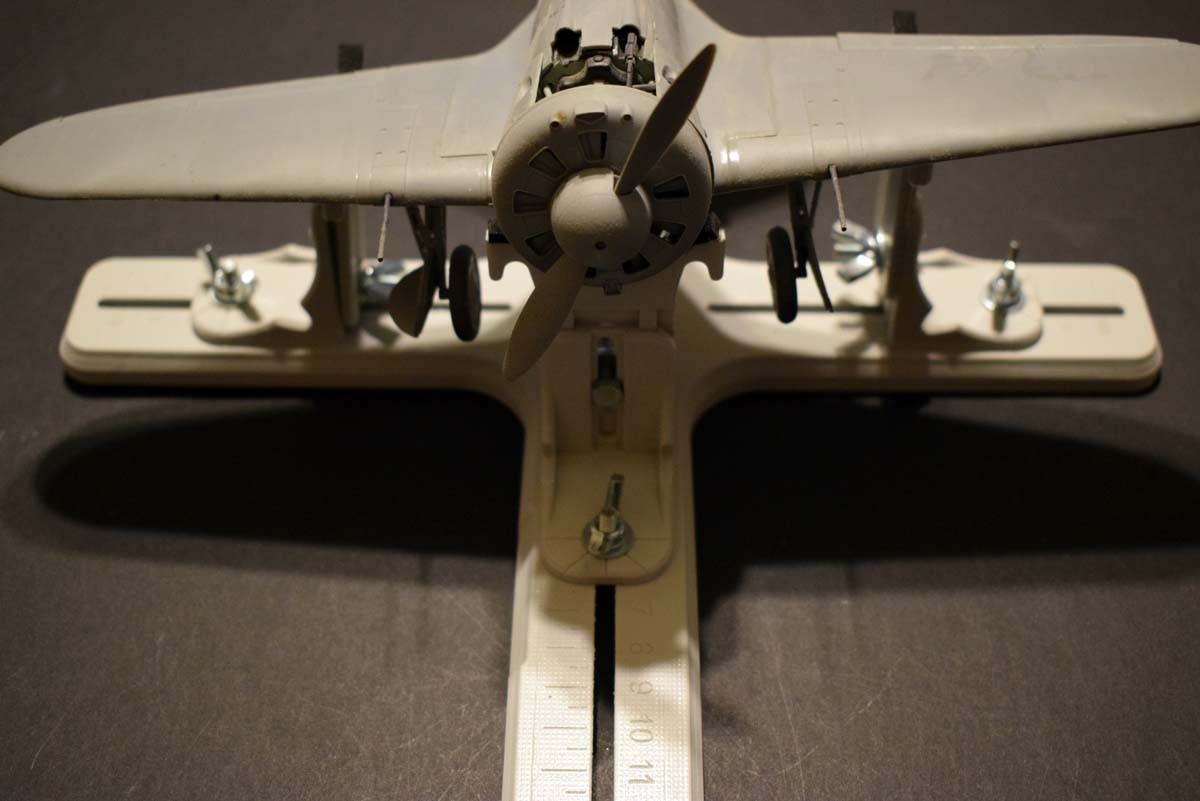

The grooves on the underside of the cruciform capture the head of the bolt and prevent rotation when you tighten or loosen the bolt; I did find some restriction on sliding the bolt, but that can be overcome via a quick spray of WD40 which has a 1001 uses. The bolt is then used to secure angle brackets using a butterfly nut and a washer. The model support arms are attached via the same method with the slide being held in alignment via 2 grooves. In order to protect the model there are foam sleeves on the supports and I would like to see spares of these included or made available.

The support arms vary in size depending on which one you purchase, but my gut says that due to the distances that can be obtained I suggest you buy the biggest you will need as it will be up to supporting a model up to its maximum and down to very small. The fuselage supports may need extra foam of a different profile to be scratched, but I cannot foresee any other issues of using these for multiple scales. I flexed the cruciform of the largest jig and while a small amount of movement occurred I at no time had concerns about it breaking it. All told other than the foam coming off of the supports the jig should last very many years, even if used for a painting support. There are measurements in 5mmincrements that will add the modeller in setting the jig up prior to introducing the model which is a nice touch.

The design of all elements has been well thought out and I could only come up with 2 potential changes that may aid the modeller. The first of these would be to add a raised welt on the underside of the angles that would insure that the arms are straight, but I have to consider the effect that change would have in the overall distance that could be obtained between the arms as it would be reduced. The second change is the measurements marked on the cruciform should be from the centre point rather than the slide cut-out. I would have liked to see a couple of nuts, bolts and washers included in each set to cover losses.

Conclusion

Taking a look over these jigs I can see their usefulness to the modeller and can even see some arm support modifications that would make them more applicable to the armour/vehicle modeller looking for a support jig. The design and functionality meets the needs of supporting the types of model for which intended. The strength of the parts also meet my expectations and I feel a deliberate attempt would be needed to break them. I did encounter an issue with some of the butterfly nuts and contacted the company about the issue; I was informed that a new supplier had been sourced and the issue should no longer be found; I was promised that a replacement service was available for those encountering an issue. I myself can see these being of most use during the application of small parts such as aerials and during the application of decals, paint and weathering. The result of all this is a robust jig that offers options that wooden offerings cannot compete with.

![MiG-3 [late] ‘Winter Air Defence’ Incoming](/upload/media/posts/2025-06/20/mig-3-late-winter-air-defence-incoming_1750437150-s.jpg)